Skills Development

iSchematic utilizes machine-specific information that trains your technicians to become a master troubleshooter by capturing how a machine works from the most basic level to its complex sequence of events.

We achieve this by developing each technician's knowledege of the components and operating events of your specific equipment – from new hires to 20-year veterans. iSchematic presents essential maintenance information about your machine so your workforce can learn and build upon their skills.

Our approach contains facets that define the level of understanding a technician possesses. Workers start with awareness, build to comprehension, advance to skilled, and end in mastery.

1) Awareness:

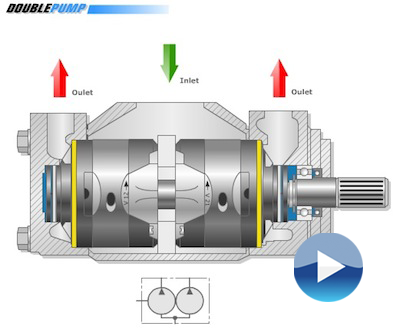

A technician is aware of a machine's function when he has a general understanding of what a specific component is and how it should function – this level of understanding is fundamental for any technician. iSchematic breaks each machine down to its individual components, which gives your technician access to general information about each component, including an animation illustrating how it operates.

2) Comprehension:

Comprehension occurs when a technician understands the specific role of a component within an entire machine. iSchematic builds on a technician's awareness by describing how the component functions within the machine. Workers understand how the component is energized, specific fluid movement, and its effect on other components.

3) Skilled:

A skilled technician combines the specific processes of different components to understand the intricacies of a single event. iSchematic displays the fluid flow for every event within your machine. Your technicians can follow the dedicated lines to trace potential failures within the system.

4) Mastery:

Technicians become master troubleshooters when they are able to apply knowledge of specific component functions, their roles, and events that occur within a machine that are required for its complete operation. iSchematic Online and Modules foster a high level of machine understanding by positioning these stages within a revolutionary and easy-to-use-tool which enables your technicians to become effective troubleshooters.

TPC Training Systems

IntelliSchematic's sister company, TPC Training Systems, provides industrial skills and safety training programs across all industries. For over 40 years, we have delivered both off-the-shelf and custom technical skills programs for clients seeking maintenance training, plant training, and manufacturing training.

TPC Training uses multiple delivery options to meet clients' unique training needs. For self-paced training, our online courses and self-study manuals allow employees to learn at their own pace. For group training sessions, our instructor-led classes provide hands-on, machine-specific training. Employees exposed to both training methods exhibit greater retention and improved productivity.

In addition, TPC Training also offers a range of consulting services. Our services include the development of facility-specific courses, creation of documentation and procedures, and on-site workshops to develop trainers' skills.

Explore our website and discover why 40,000 clients have counted on us to train their 3.2 million workers.