a product of Intellischematic

Contact an IntelliSchematic Consultant: Here

Equipment Documentation Hub

iSchematic is a comprehensive application that collects machine documents and workforce insight to create an interactive, web-based application. iSchematic assembles knowledge from your maintenance technicians and builds a valuable information asset that is easily accessed and applied throughout your company.

iSchematic reaches beyond simply recording generic component information by building upon machine-specific knowledge and safety information acquired by your workforce while working in the field. iSchematic enables your company to capture tangible data from your workforce and make it accessible before it is lost.

Features

- Clean, intuitive user interface.

- Convenient resource library access – contains hundreds of animations, descriptions, and symbols for hydraulic, electrical, drives and controls, pneumatic, mechanical, and PLC systems.

- Ability to add unique content to the resource library and customize its output.

- Establish permissions to govern module viewing and control updates.

- "Product notes" and integrated email notifications communicate updates.

Collaborate While Troubleshooting

iSchematic connects your people to your facility's processes. This gateway allows your workforce to interact with your machine and system information while giving supervisors a platform to perform continuous updates and additions. iSchematic Online generates a living document out of your workforce's collective expertise that develops into an invaluable tool within your company.

iSchematic Production

1) Gather Information:

We start by evaluating the information you already have on site. From your machine schematics and bill of materials (BOM), we identify:

- Your machine's events

- Relevant machine components

2) Verify Your Documentation:

After we identify the relevant events and components, our engineer will visit your site to examine the machine in person. He will then note any modifications to your machine's schematics and photograph the relevant components.

3) iSchematic Setup:

After the IntelliSchematic engineer leaves your site, he will then create detailed sequences of operation for each event, and identify each component within the photos.

4) Creating Your iSchematics:

The engineer will hand your iSchematics over to our production technician. The production tech will then transfer all of your information into iSchematic Online and create your iSchematic Modules.

5) Download:

After your iSchematic Modules are completed, they will be available for download and ready to use on your desktop, laptop, or tablet.

iSchematic Troubleshooting Modules

The custom-built iSchematic Modules are the sole source for information on any machine in your facility. iSchematic is designed to provide critical machine and process information to your workforce on an interactive and engaging platform. Reduce machine downtime and improve equipment utilization by placing advanced machine-specific content at your technicians' fingertips. iSchematic Modules convert experience into accessible data, which ensure your machine's history isn't lost as your company grows.

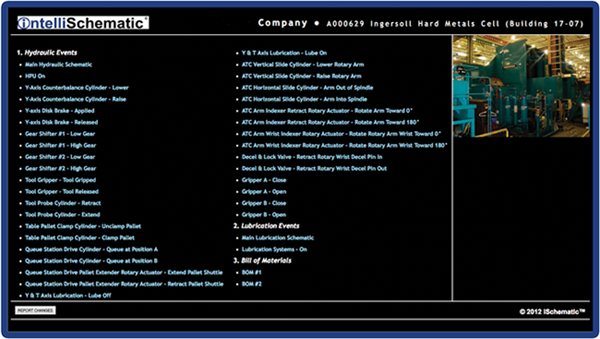

Operating Events

The events page lists all of the events that occur within the machine. Here the user can access the Main Schematic, the Bill of Materials, and dial-in to individual events occurring during the machine's operation.

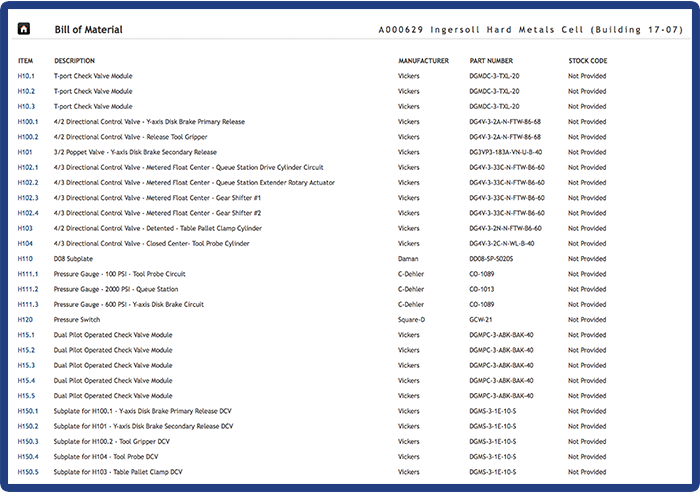

Bill of Materials

The BOM lists the component number, description of the component, manufacturer name, part number and stock code of every component running the machine. The BOM provides a complete snapshot of these components.

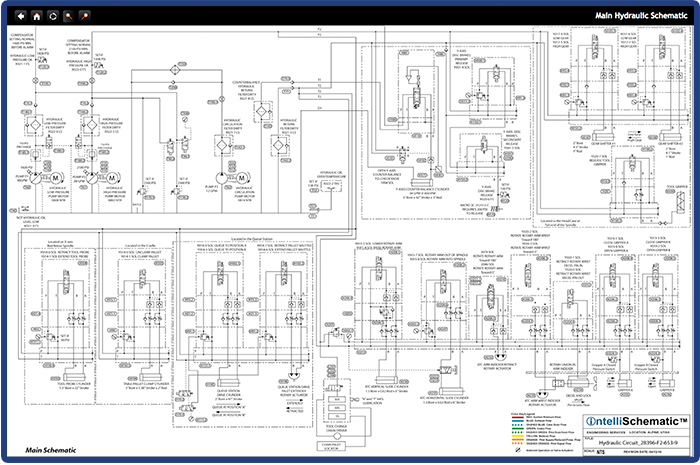

Main Schematic

The Main Schematic lets the user see the overall function of the machine without highlighting the specific events. Your workers see a complete view of the machine's processes and can access each individual component page.

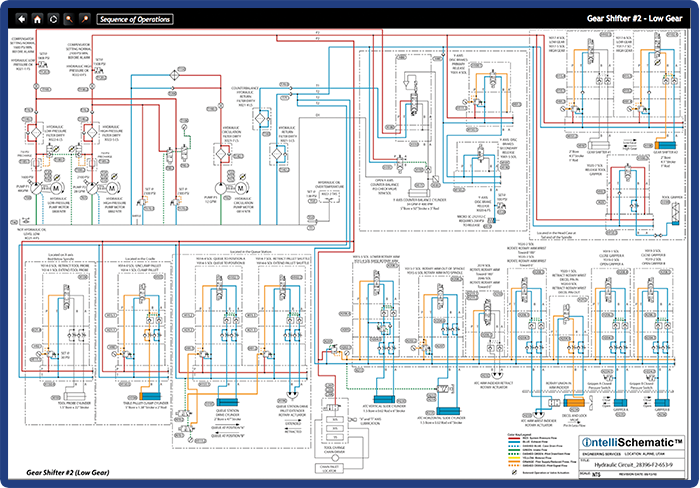

Event Schematic

These specialty-made schematics highlight the separate components that work to perform the machine's function. By showing fluid and electrical current movement, and using easy to identify graphics, technicians can isolate a single event from the main schematic.

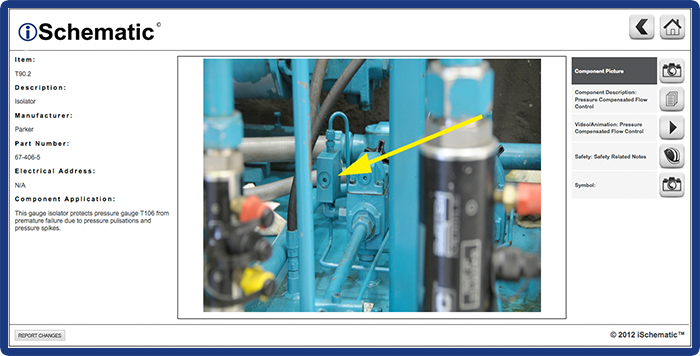

Component Page

The component page showcases a specific component working within an event. From this page, your technicians can access information including: a picture of the actual component working in your machine, a description of the component, a video that illustrates how the component should function, and safety-related information. Here, the maintenance technician has the necessary information to troubleshoot a down machine.